KEPUNI provides the most professional automatic welding equipment for thin-walled tube sheets. With years of on-site experience and integrated expert database system, the automatically generated expert parameters are more reliable, ensuring that each weld can achieve the best welding effect.

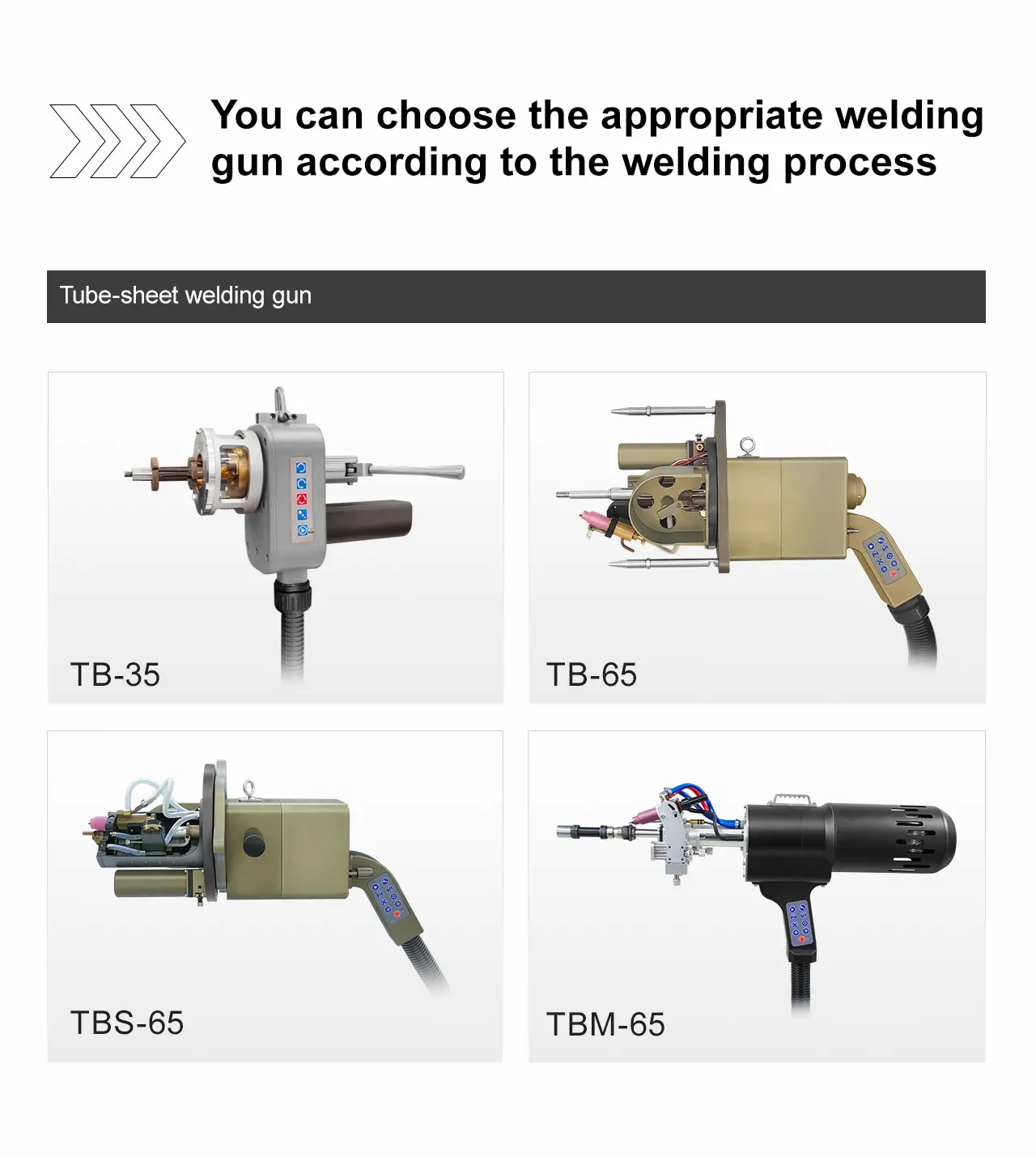

Adapted weld head: TB-35/TB-65/TBM-65/TBS-65

Welding material: Stainless steel, carbon steel, titanium, nickel .etc

Welding wall thickness: ≤ 5mm

Expert database: To make programming simpler and welding more reliable

Parameter printing: Provide parameters such as current, voltage, rotation speed, and swing speed for each welding interval to optimize the welding effect in the later stage

Perfect interval segmentation and parameter saving functions, which

can be changed, retrieved, and saved according to different welding

process requirements

It can achieve welding simulation function and

timely discover problems that may arise when current parameters are

applied to actual welding

The equipment has functions such as

tungsten short circuit protection, motor overload protection, current

monitoring, water flow detection, nitrogen deficiency monitoring, and

fault prompt.

Key Features: Adaptive Weld Heads: Equipped with XD-35/XD-65 models, the machine accommodates a wide range of tube sizes and configurations.

Material Compatibility: Welds stainless steel, carbon steel, titanium, nickel alloys, and other specialty metals.

Wall Thickness Capacity: Handles materials up to ≤5 mm with minimal heat input, reducing distortion risks.

Expert Database: Simplifies programming by storing pre-verified parameters for quick recall, enhancing process repeatability.

Real-Time Parameter Logging: Captures current, voltage,

rotation speed, and swing speed for each welding interval, enabling

post-weld analysis and optimization.

Flexible Interval Segmentation: Allows customization of welding parameters across segments to address complex joint requirements.

Welding Simulation: Predicts potential defects (e.g., inadequate fusion, spatter) before execution, minimizing trial-and-error adjustments.

Safety and Monitoring: Tungsten Short-Circuit Protection: Prevents electrode damage.

Motor Overload Detection: Safeguards mechanical components during high-duty cycles.

Coolant Flow Verification: Ensures optimal thermal management.

Argon Gas Monitoring: Maintains inert atmosphere integrity for reactive metals.

Fault Diagnostics: Provides clear error codes for rapid troubleshooting.

By combining intelligent automation with robust safety features,

KEPUNI’s machine reduces setup time, scrap rates, and operator

dependency, making it ideal for industries requiring flawless welds

under stringent quality standards.

The KEPUNI TB-35 orbital welding head uses a pneumatic core expansion for self-centering clamping on thin-walled tubes (≤2...

Achieve rapid, high-quality tube-sheet welds. The TBS-65's unique design enables quick setup and stable operation with bui...

The KEPUNI TBM-65 automatic welding head uses a pneumatic core expansion system to self-center and firmly clamp in pipes (...

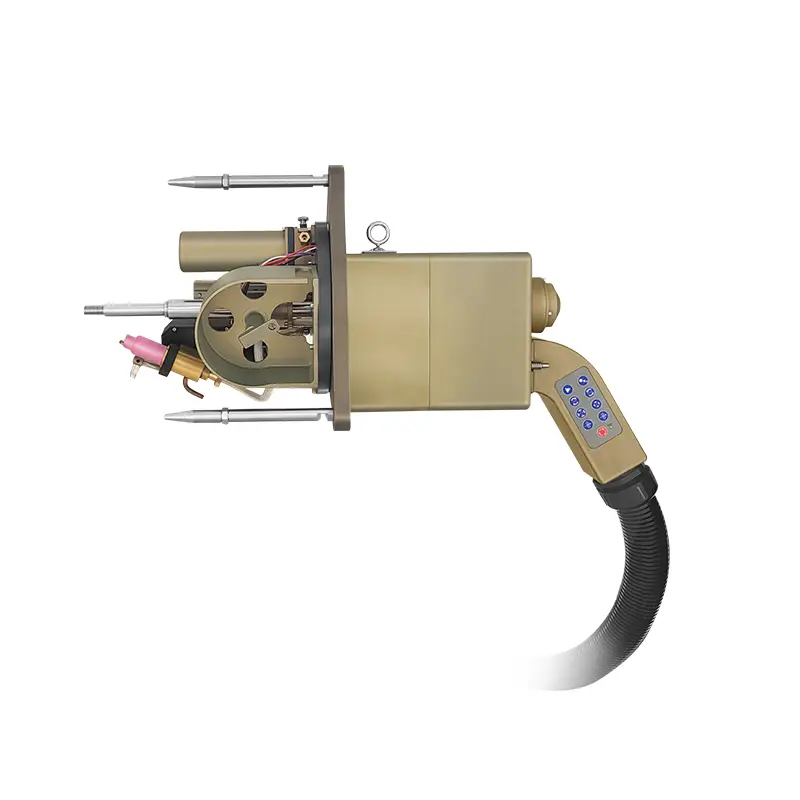

Leverage an expert database for reliable, perfect welds. The KEPUNI TB-65 auto welding head features parameter printing &a...

KEPUNI's orbital welding system pairs intelligent controls (expert database, weld simulation, parameter logging) with vers...