The tube facing machine provided by KEPUNI uses non-polluting cold working as the cutting method to cut the pipe end, to make the pipe end flat and smooth and the closed processing environment is safer and more reliable.

It can machining copper, iron, aluminum, steel, titanium alloy and other alloy steel, ect

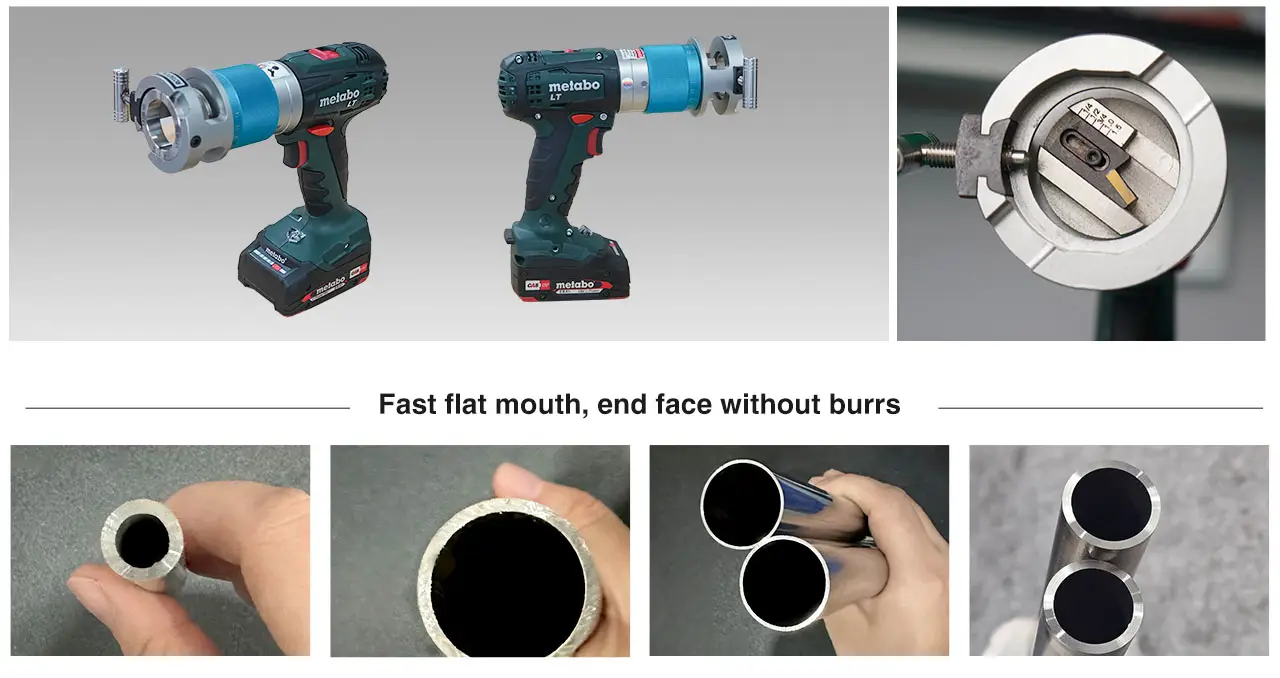

Using Metabo motor, sufficient power, precision and stability

Cold working process, no damage to the substrate material

Closed processing method, using safe and reliable

Small size, fast and safe one-to-one fixture clamping.

The precision feed design is more precise, and the cutting volume can be fine-tuned.

KEPUNI’s tube facing machine employs non-polluting cold-working

technology to achieve flawless pipe end preparation, ensuring a flat,

burr-free surface while maintaining material integrity. The fully

enclosed processing environment prioritizes operator safety and process

reliability, making it ideal for industries with stringent quality and

safety standards.

Key Features: Broad Material Compatibility High-Performance Metabo Motor Cold-Working Advantage Enclosed Processing Chamber Compact Design with Rapid Clamping Precision Feed Control Applications: Aerospace: Prepares titanium and nickel-alloy pipes for hydraulic and fuel systems.

Semiconductor Manufacturing: Delivers ultra-clean end faces for vacuum-compatible tubing.

Nuclear Power: Complies with ASME Section III codes for reactor piping integrity.

By combining advanced motor technology, safety-focused design, and

precision engineering, KEPUNI’s tube facing machine reduces material

waste, enhances productivity, and meets the most demanding quality

control requirements.

Machines copper, iron,

aluminum, carbon steel, stainless steel, titanium alloys, and other

specialty metals with equal precision.

Driven by a Metabo

industrial-grade motor, the machine delivers consistent power, torque,

and stability, even for heavy-duty applications.

Eliminates heat-affected zones (HAZ)

and work hardening, preserving the substrate’s mechanical properties

and corrosion resistance.

A dust-tight, sealed workspace

minimizes exposure to metal particles and noise, ensuring compliance

with OSHA and EU safety regulations.

Features a one-to-one quick-change fixture for fast, secure pipe clamping, reducing setup time by up to 50%.

Micro-adjustable cutting depth

(±0.01 mm) enables fine-tuning of material removal, ensuring consistent

end face perpendicularity and surface finish.

Portable flat mouth machine

| Model | Unit | XD1.0DCB/AC | XD1.5DC/AC | XD2.5DC | XD4.5 |

| Cutting range | mm | 3-25.4 | 3.175-38.1 | 4.76-63.5 | 6.35-114.3 |

| Inch | 1/8"-1.0" | 0.125"-1.5" | 0.1875"-2.5" | 0.25"-4.5" | |

| Max cutting wall thickness | mm | 3 | 4 | 3 | 10 |

| Power | w | 300 | 300 | 300 | 1020 |

| Voltage | V | 10.8VDCLi | 14.4VDCLi | 14.4VDCLi | 220/110VAC |

| Rotating speed | RPM | 350 | 400 | 400 | 140 |

| Weight | kg | 2 | 2.5 | 4 | 19 |

Plug-in flat mouth machine

| Model | Unit | XF1.0DC/AC | XF1.5DC/AC | XF2.5DC/AC | XF3.0AC | XF4.5 |

| Cutting range | mm | 3-25.4 | 3.175-38.1 | 4.76-63.5 | 12-76.2 | 6.35-114.3 |

| Inch | 1/8"-1.0" | 0.125"-1.5" | 0.1875"-2.5" | 0.5"-3.0" | 0.25"-4.5" | |

| Max. cutting wall thickness | mm | 3 | 4 | 3 | 6 | 10 |

| Power | w | 1300 | 1300 | 1300 | 1300 | 1300 |

| Voltage | V | 10.8VDCLi | 14.4VDCLi | 14.4VDCLi | 220VAC | 220/110VAC |

| Rotating speed | RPM | 350 | 400 | 400 | 450 | 140 |

| Weight | kg | 2 | 3 | 3.5 | 3.8 | 19 |

KEPUNI's professional tungsten grinder ensures fast, precise sharpening for electrodes (1.0-3.2mm). Featuring a powerful D...

KEPUNI's tube facing machine delivers safe, high-quality pipe end prep via precision cold-cutting. The closed, environment...

KEPUNI's planetary pipe cutter delivers clean, burr-free cuts & uniform bevels via a static cold-cutting process. Feat...