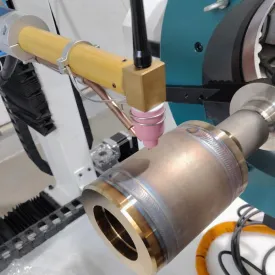

As an advanced general-purpose automatic welding machine, the Pipe Circumferential Seam Automatic Welder utilizes sophisticated control programs and components to automatically complete various circular and circumferential welds. It is particularly well-suited for butt welds and fillet welds on pipe fittings. Its wide range of applications includes precise circumferential welds within the diameter range of circular workpieces, including those on cylinders, tees, elbows, pipe flanges, and lap joints. The machine's dimensions can be customized to meet diverse production scenarios.

The fully automatic girth welder utilizes the TIG welding process and can be filled with filler wire or self-melting. It is suitable for high-quality welding of materials such as stainless steel, carbon steel, and titanium alloys. Its products are widely used in industries such as petrochemicals, medical machinery, instrumentation, and environmental protection equipment, providing solid technical support for production and manufacturing in various industries.

Compared with traditional manual welding, automated welding equipment has stable and reliable performance, and can effectively reduce the problems of unstable quality and low production efficiency of traditional manual welding. Many powerful companies have introduced fully automatic circumferential seam welding equipment to improve their own production output capacity, enhance their ability to respond quickly to the market, and occupy an advantageous position in the fierce market competition.

The fully automatic girth welder utilizes the TIG welding process and can be filled with filler wire or self-melting. It is suitable for high-quality welding of materials such as stainless steel, carbon steel, and titanium alloys. Its products are widely used in industries such as petrochemicals, medical machinery, instrumentation, and environmental protection equipment, providing solid technical support for production and manufacturing in various industries.

The XD-GH400, independently developed, designed, and manufactured by KEPUNI, is a dedicated power supply for automatic TIG circumferential welding of pipes with a built-in welding database. This 400A welding power supply integrates the welding core, control module, arc voltage tracking, torch oscillation, integrated wire feeder, circulating cooling water fan, printer module, IoT module, USB download interface, and other hardware and program control. Based on information such as pipe diameter and wall thickness, it automatically generates all required welding parameters, offering simple and easy operation.

Key Features:

• Siemens PLC+DSP digital signal control ensures more precise arc output. The 400A welding current combined with high-frequency ceramic arc ignition technology ensures easy and reliable arc starting.

• Circular automatic welding program ensures more stable current output and automatically controls parameters such as current output, wire feed speed, arc voltage tracking, torch oscillation, positioner, and circulating water.

• Built-in pipe welding V2.0 database: users simply enter the pipe diameter, wall thickness, or wire diameter, and the system automatically generates welding parameters.

• A built-in cold water tank and an Italian-imported water pump provide longer head and improved cooling, allowing the welding torch to operate for extended periods.

• A built-in IoT module supports remote control program upgrades. A built-in USB port enables industrial interconnection, allowing users to import and export welding parameters or directly download them for use.

• Dual operation modes: industrial touch screen and manual control box, with integrated buttons, support dual-control seam joints.

The positioner is driven by a servo motor and features a 400mm base with a three-jaw chuck. The main machine adopts a six-axis design, enabling left-right, up-down, and forward-backward adjustments of the welding gun to meet the welding requirements of straight pipe to straight pipe, straight pipe to elbow, straight pipe to tee, and straight pipe to flange.

The welding gun adopts the standard TiG water-cooled 500A welding gun design, which can work continuously for a long time. The welding gun mechanism is equipped with an arc voltage height adjustment device and a welding gun angle swing device, which can realize automatic or manual swing and adjustment.

The wire feeding mechanism adopts a V-shaped serrated wire feeding wheel and a high-precision motor, which can feed the wire smoothly and evenly, supports 0.8mm-1.6mm welding wire, and effectively avoids wire sticking.

With its advanced technology, excellent performance and rich functions, KEPUNI pipeline fully automatic girth welder brings efficient, intelligent and stable solutions to the pipeline welding industry. It is an indispensable welding tool in modern industrial production.