As a professional precision pipe welding machine, it perfectly meets the stringent welding requirements of high-precision industries and is an indispensable high-quality welding tool in this field. It is widely used in electronic components (such as welding 3.175mm ultra-thin tubes), nuclear power pipelines, military equipment, electronics, instrumentation, and other industries

XD-8HPH features:

1、Single-tube, single-clamp design:

Each pipe diameter is matched with a dedicated customized fixed clamp to ensure a perfect fit between the welding gun and the pipe, thus eliminating the adaptation error of universal welding clamps.

2、Efficient air-cooling architecture:

Optimized air-cooling channels achieve rapid heat dissipation, enhance durability, and enable long-term continuous operation.

3、Ultra-short line segment welding capability

The breakthrough 6mm shortest straight line segment welding technology solves the industry pain point that traditional welding heads cannot operate in narrow spaces.

4、Ultra-High-Temperature-Resistant Non-Metallic Head Body

The welding gun's core is constructed from a non-metallic, high-temperature-resistant material. Compared to traditional metal gun bodies, it offers superior heat resistance, capable of withstanding temperatures exceeding 1000°C. Under continuous high-temperature conditions, its service life is increased by 300%, ensuring immediate operation. This effectively prevents the risk of gun burnout and carbonization caused by temperatures exceeding 1000°C, ensuring stable and reliable welding operations.

5、German Z-series high-strength alloy gear technology

We selected German Z-series alloy gears for key component design. These gears undergo specialized heat treatment and precision machining, resulting in exceptional strength and wear resistance. By optimizing arc shape and energy distribution, arc stability is improved by 50% compared to traditional designs. Furthermore, their high strength and wear resistance effectively reduce sparking and other anomalies caused by component wear, ensuring safe and reliable welding operations.

Detailed analysis of welding gun structure:

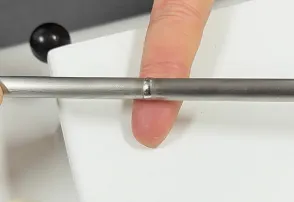

Push-pull rod system

Controls the opening and closing of the welding clamp mechanism, adopts a two-stage design to ensure that the welding clamp is tightly closed.

Welding head main structure

Reliably clamps pipe fittings and connects and positions tungsten needles, thus achieving precise welding operations.

Quick closing lever

Allows the clamp body to close quickly.

The KEPUNI 8HPH benchtop orbital welding head, with its wide range of applications, exceptional performance, and sophisticated design, has become the undisputed choice for high-precision pipe welding. It not only provides customers with efficient, high-quality welding solutions, but also drives the industry toward higher precision and efficiency.