Kepuni Showcases Innovative Orbital Welding Solutions at Shanghai Essen Welding & Cutting Fair 2025

Global leader in orbital welding technology highlights precision and automation for industrial applications.

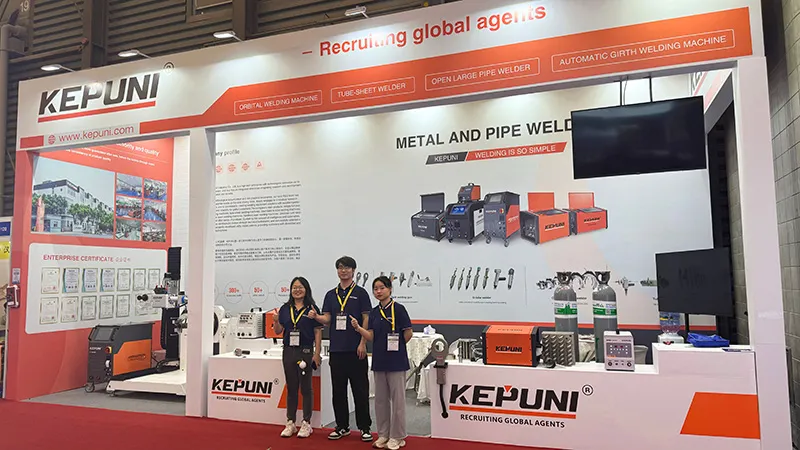

[Shanghai, China] – [Date of Release] – Kepuni, a globally recognized supplier of high-precision orbital welding systems, participated in the 28th edition of the Shanghai Essen Welding & Cutting Fair (also known as the Beijing Essen Welding & Cutting Exhibition) in 2025. The event, held at the Shanghai New International Expo Center from June 17 to 20, 2025, served as a pivotal platform for industry leaders to demonstrate advancements in welding and cutting technologies. Kepuni seized the opportunity to highlight its cutting-edge orbital welding equipment, designed to address the growing demand for efficiency, consistency, and automation in sectors such as HVAC-R, frozen food processing, and industrial manufacturing.

The Shanghai Essen Welding & Cutting Fair, a cornerstone event for the global welding industry, attracted over 800 exhibitors and thousands of professional visitors, including 14,043 attendees on the first day alone, with 1,293 overseas guests from 84 countries. Against this backdrop of innovation and collaboration, Kepuni presented its flagship orbital welding solutions, emphasizing their ability to deliver leak-proof, high-integrity welds critical for piping systems in demanding environments. Live demonstrations at the Kepuni booth illustrated the machines' user-friendly operation, reliability, and adaptability to materials like stainless steel and copper tubing—key components in refrigeration and food processing infrastructure.

Key Highlights from Kepuni’s Participation:

Precision and Automation for Diverse Industries: Kepuni’s orbital welders address the need for flawless piping systems in HVAC-R and frozen food processing, where even minor weld defects can lead to leaks, energy loss, or contamination. By automating the tungsten gas shielded arc welding (GTAW) process, Kepuni’s equipment ensures consistent, high-quality results.

Live Demonstrations and Technical Expertise: Attendees experienced firsthand the ease of use and precision of Kepuni’s systems, which feature intuitive controls and real-time monitoring capabilities. The company’s engineers were on hand to discuss customized solutions for complex applications.

Alignment with Industry Trends: The fair emphasized themes like smart manufacturing and automation, with dedicated zones for laser technologies and robotics. Kepuni’s focus on automated welding resonated with these trends, positioning the company as a forward-thinking partner for industries navigating labor shortages and quality challenges.

Quotation from a Kepuni Representative:

"We are thrilled to have connected with so many international professionals at the Shanghai Essen Welding & Cutting Fair. At Kepuni, we believe orbital welding is not just about equipment—it’s about providing reliable solutions that enhance safety and productivity. This event allowed us to demonstrate how our technology can help clients across the HVAC-R and food processing sectors build more resilient and efficient operations."

About Kepuni:

Kepuni is a trusted global supplier of orbital welding equipment and solutions, serving industries where weld quality is non-negotiable, including oil and gas, semiconductors, pharmaceuticals, and food processing. With a commitment to innovation and supported by a worldwide service network, Kepuni empowers clients to achieve superior operational efficiency and long-term reliability.